AI Orchestrates Coca-Cola’s Global Orange Supply, Saving $32M and Protecting Quality

Reliable Quality, Lower Costs:

The Coca-Cola Company

Coca-Cola needed to source oranges from multiple continents, balancing availability, cost, and agronomic variability while still meeting strict quality and taste standards at global scale.

Seasonal swings, crop disease, weather shocks, and regional price volatility made it difficult to ensure reliable, cost-efficient supply for a complex, high-volume manufacturing network. Traditional planning processes could not fully account for interactions between demand, sourcing, transport modes, blending formulas, and plant constraints, leading to avoidable costs and inconsistent product experience.

The organization required a way to simulate and optimize end-to-end decisions—what to buy, where to move it, how to blend and bottle—to keep margins and quality aligned.

$12M

$20M

6

Decreased manufacturing costs

Reduced raw materials costs

Month deployment

The Challenge

Coca-Cola needed to source oranges from multiple continents, balancing availability, cost, and agronomic variability while still meeting strict quality and taste standards at global scale.

Seasonal swings, crop disease, weather shocks, and regional price volatility made it difficult to ensure reliable, cost-efficient supply for a complex, high-volume manufacturing network. Traditional planning processes could not fully account for interactions between demand, sourcing, transport modes, blending formulas, and plant constraints, leading to avoidable costs and inconsistent product experience.

The organization required a way to simulate and optimize end-to-end decisions—what to buy, where to move it, how to blend and bottle—to keep margins and quality aligned.

PrimeAI’s Solution

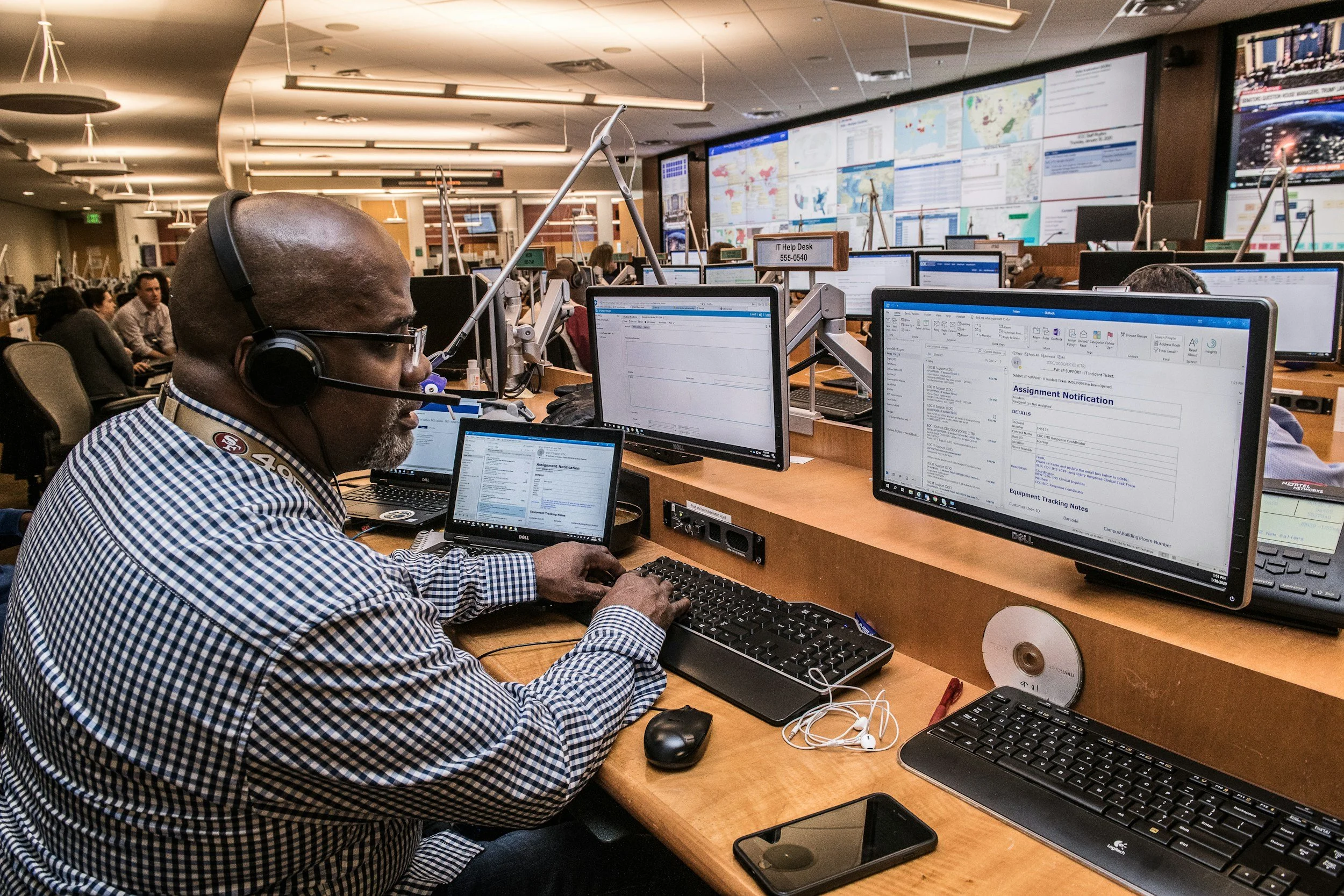

Optimization engines evaluated ocean and ground transportation options, dynamically routing fruit and concentrates to the best plants based on cost, lead time, and quality impact.

Blending and formulation models recommended ingredient mixes that met strict sensory and quality targets while flexing between origins to mitigate crop and price shocks.

PrimeAI also optimized packaging and storage decisions, aligning inventory policies and safety stocks with forecasted demand and plant capacities to minimize waste and handling costs.

The Results

Over roughly 6 months, PrimeAI deployed demand forecasting, adaptive production scheduling, optimized routing, and multi-resource allocation into Coca-Cola’s planning workflows. Manufacturing costs decreased by $12M through smarter line utilization, reduced changeovers, and better alignment of production plans with true demand.

Raw material costs fell by $20M as sourcing, transport, and blending decisions systematically shifted toward lower-cost combinations without sacrificing quality.

Coca-Cola achieved more consistent product taste and greater operational adaptability, rapidly adjusting plans when supply shocks or demand changes hit, strengthening both resilience and profitability.

Customer Success Stories